Omori Flow Wrappers

Omori North America redefines food packaging with our state-of-the-art flow wrappers. Known for their versatility and speed, our machines efficiently wrap individual food items in a continuous flow of packaging material.

Ideal for applications in cheese, bakery, confectionary, whole muscle and former meat products, and consumer packaged goods. Equipped with innovative servo motor-driven horizontal form-fill technology, Omori Flow Wrappers offer unparalleled precision and reliability.

With the ability to wrap multiple products in a single bag, including gas flushing for extended shelf life or streamlined transportation, our machines operate at speeds of up to 300 packages per minute. Explore Omori North America’s cutting-edge flow wrappers—defining the future of food packaging.

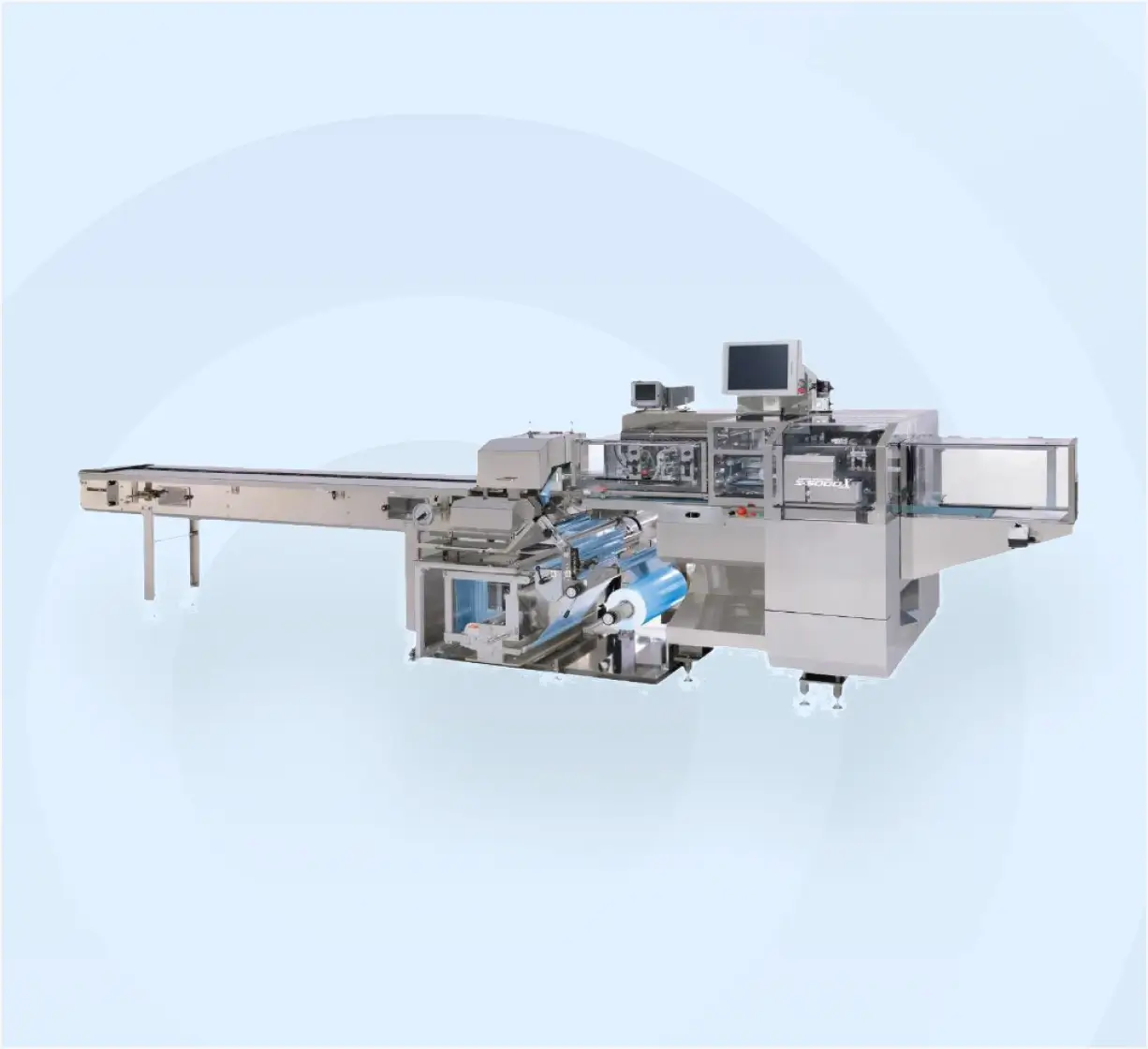

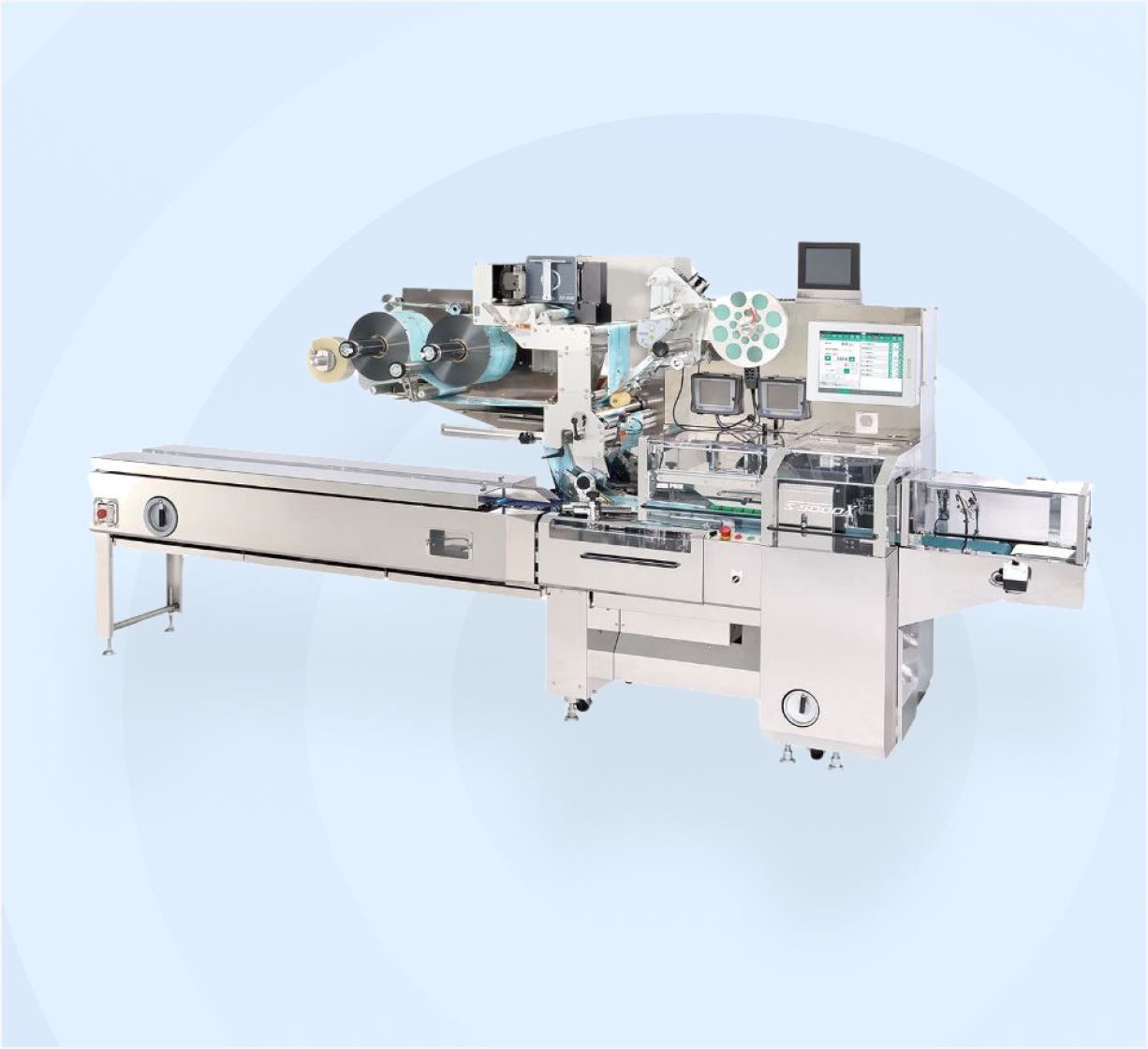

S-5000X Series

Speeds up to 300 packages per minute. Applications include: cheese, bakery, confectionery, whole muscle and former meat products, and consumer packaged goods.

S-5710X-BX-BIF Master Packer

With speeds up to 40 packages per minute , this is the perfect solution for wrapping multiple products in a single bag. Place up to 4 packages per single bag, gas flushed or shrink wrapped for extended shelf life and ease of transportation.

Pa-2000 Series

The Pa-2000 Series is an entry level unit that can run up to 80 packages per minute. Applications include: cheese, bakery, confectionery, whole muscle and former meat products, and consumer packaged goods.

Omori Flow Wrappers

Omori North America redefines food packaging with our state-of-the-art flow wrappers. Known for their versatility and speed, our machines efficiently wrap individual food items in a continuous flow of packaging material.

Ideal for applications in cheese, bakery, confectionary, whole muscle and former meat products, and consumer packaged goods. Equipped with innovative servo motor-driven horizontal form-fill technology, Omori Flow Wrappers offer unparalleled precision and reliability.

With the ability to wrap multiple products in a single bag, including gas flushing for extended shelf life or streamlined transportation, our machines operate at speeds of up to 300 packages per minute. Explore Omori North America’s cutting-edge flow wrappers—defining the future of food packaging.

S-5000X Series

Speeds up to 300 packages per minute. Applications include: cheese, bakery, confectionery, whole muscle and former meat products, and consumer packaged goods.

S-5710X-BX-BIF Master Packer

With speeds up to 40 packages per minute , this is the perfect solution for wrapping multiple products in a single bag. Place up to 4 packages per single bag, gas flushed or shrink wrapped for extended shelf life and ease of transportation.

Pa-2000 Series

The Pa-2000 Series is an entry level unit that can run up to 80 packages per minute. Applications include: cheese, bakery, confectionery, whole muscle and former meat products, and consumer packaged goods.

Frequently Asked Questions

Have a question? We have answers! Everything you need to know about Omori’s products.

What is the difference between stretch wrapper and flow wrapper?

Stretch wrappers are also called Tray Wrappers or Tray Overwrappers. Designed to wrap retail food trays using stretch film where two end flaps are folded onto the bottom of the tray. Flow wrappers are also called Horizontal Form-Fill-Seal Machines to wrap food and consumer packaged goods using heat-sealable film/shrink film and two ends are heat-sealed.

What is the range of tray sizes the Omori units can handle on stretch wrappers?

Each Omori wrapper product can accomodate a wide range of tray sizes. Please refer to the individual products specification sheet or give us a call to configure your machine.

What is the difference between the STN and STC series?

The main difference is the maximum speed – STN up to 180 trays per minute (optional) and STC up to 60 trays per minute. Talk with an Omori Sales Representative to understand which is best for you.

What is the difference between a flow wrapper and the DW-3500?

Technically, the DW-3500 can be categorized as a hybrid flow wrapper, but to differentiate the DW from regular flow wrappers, we call it an end-seal wrapper which was designed for chicken on a tray using stretchable shrink film such as Cryovac SES.

Contact Us

Have questions? Our team of customer care experts are standing by to help craft an efficient solution for your business. Complete the form below and an Omori representative will be in touch.

Our Headquarters

28 Simpson Rd

Bolton, ON

L7E 1G9

Contact Sales

Get in touch directly with our sales team by calling 905-857-7880 ext 236 or via email at sales@omori-na.com.